Box Making Machine

Product Introduction

Please click here if this video can not be played.

Please click here if this video can not be played.

Please click here if this video can not be played.

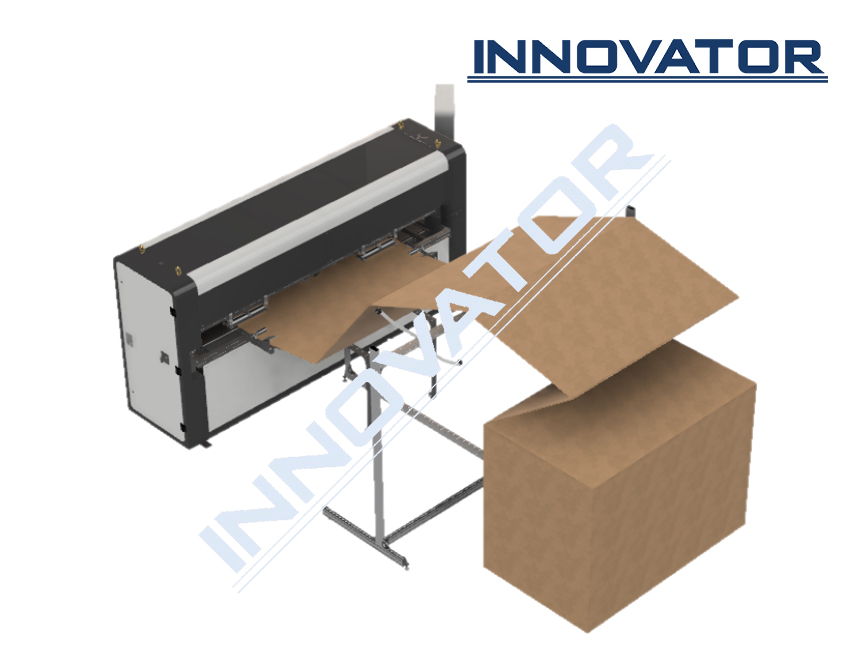

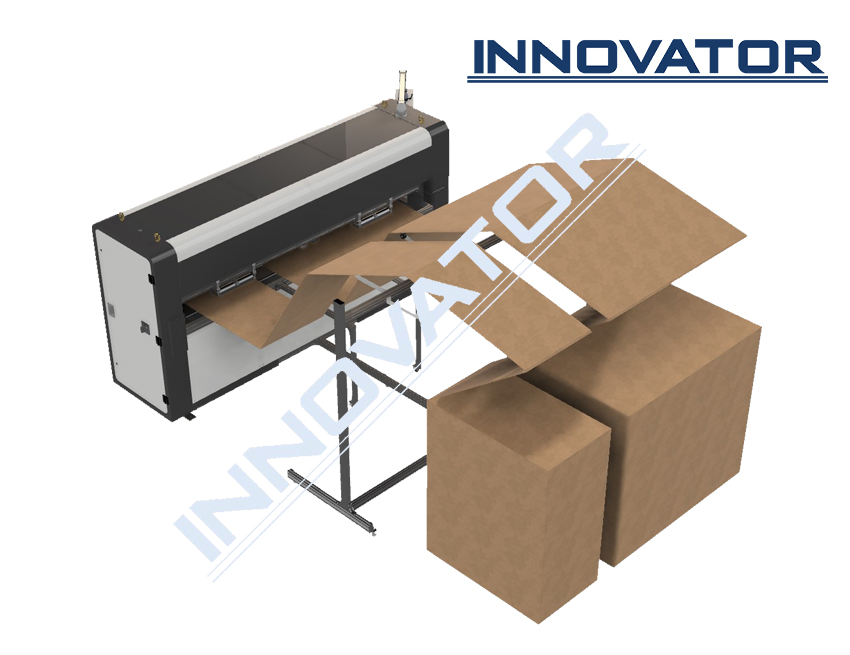

The box making machine is custom size corrugated box producing equipment. A box can be made ANYTIME when it is required reducing box warehouse management. Just select a box type on the HMI and a box with the fit size is then produced. Products can only be packaged with standard but bigger boxes BEFORE but they can be packaged with the fit-sized boxes with high efficiency for any kinds of industries NOW.

Features

- The design of the machine is complied with European safety standards.

- The model is equipped with Japan MITSUBISHI servo motor with high precision as standard. This contributes to the box making machine with great stability and accuracy of each mechanism to make fit-sized boxes.

- JAPAN MITSUBISHI PLC control system

- Blades are made of special tool steel for extended life.

- The positioning time of the longitudinal units needs only 10 seconds.

- 15-inch HMI provides the user a clear operation interface and box details.

- The HMI of the box making machine is already integrated with the industrial PC, the network connection can be done by using RJ45 cable or Wi-Fi. There is no requirement on an extra PC for the connection.

- Select a box type, enter the dimensions and a box with the fit size is then produced.

- 200 kinds of box type and size which are frequently used can be archived in the system for improving the work efficiency.

- The system will automatically save the production data for users to review. The data will include the date, time, box type, box dimension, quantity, and etc. Users can search the records based on the date.

- Remote monitoring maintenance system for faster access from the manufacturer in case of machine breakdown

- When the longitudinal units are sufficient, the feeding direction is rotatable for cardboards with insufficient width or special box types to increase machine flexibility.

- The interface will display the location of all the sensors on the machine. The user can know whether the sensors are activated by looking through the map.

- Besides the box types that exist in the system, users can edit their special box type on the interface.

- The feeding mode can be switched between manual sheet feeding and fanfold feeding.

- main working units:

- - feeding unit

- upper rubber roller of adjustable pressure

- motorized lower rubber roller

- servo-controlled speed

- creaser * 1

- circular blade * 1

- servo-controlled positioning

- circular blade with high-density teeth used for clean slitting edges

- creasers * 6

- circular blades of adjustable height * 6

- servo-controlled positioning

- circular blades with high-density teeth used for clean slitting edges

Standard in-feed Mode

- manual sheets feeding

_單張紙板手動入料_manual_sheets_feeding.jpg)

Recommended Option(s)

- automatic sheets feeding: stack cardboards with the same size for reduction of manual operation

.jpg)

.jpg)

- automatic single fanfold feeding: usable for FitSize 1600 / FitSize 2500 with single fanfold feeding

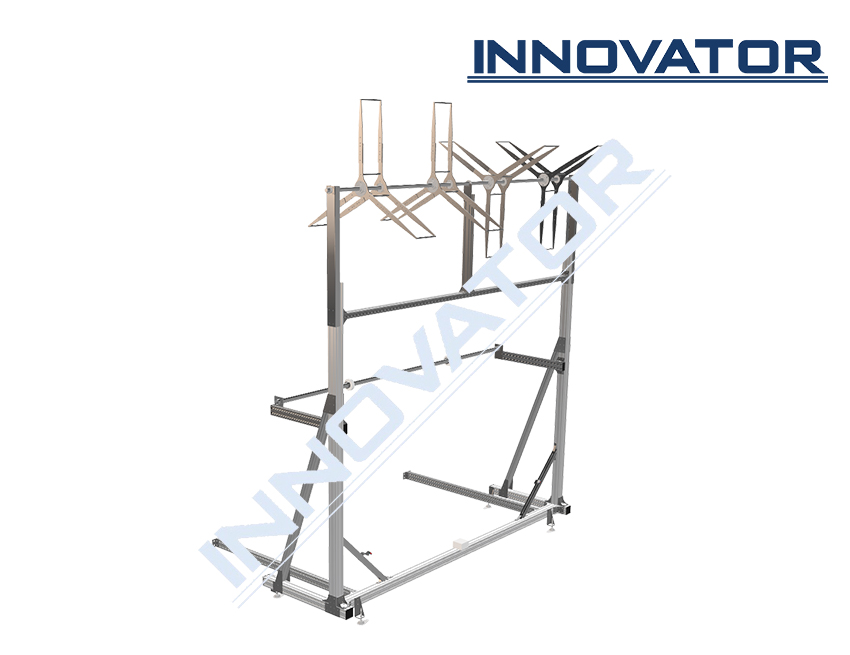

- automatic fanfold side by side feeding: The system will select the most cardboard-saving fanfold from 2 side by side fanfolds.

.jpg)

- automatic fanfold side by side feeding (rotating paper rack): It can be applied with the fanfold in 1.8 m height to reduce the creases on the feeding cardboard in the feeding process.

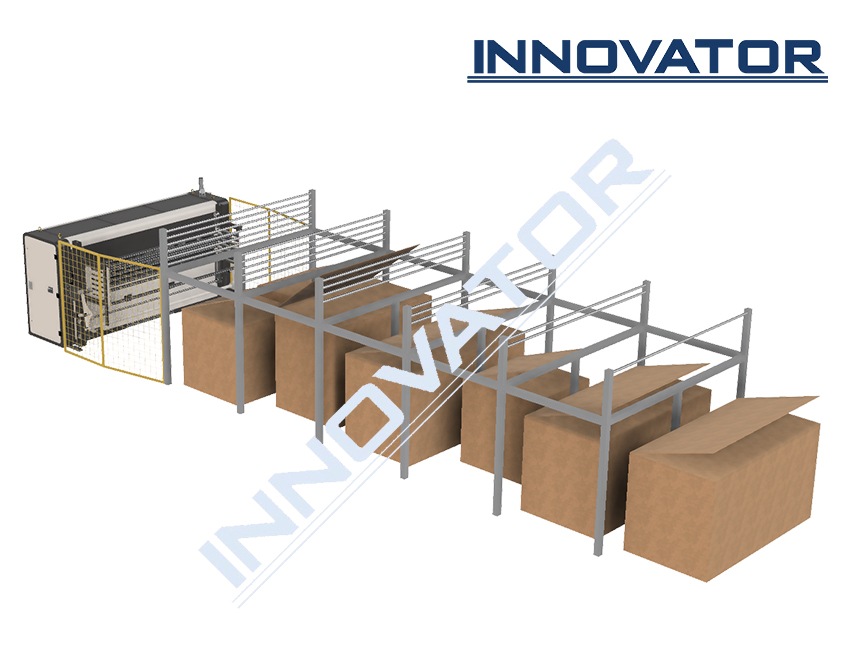

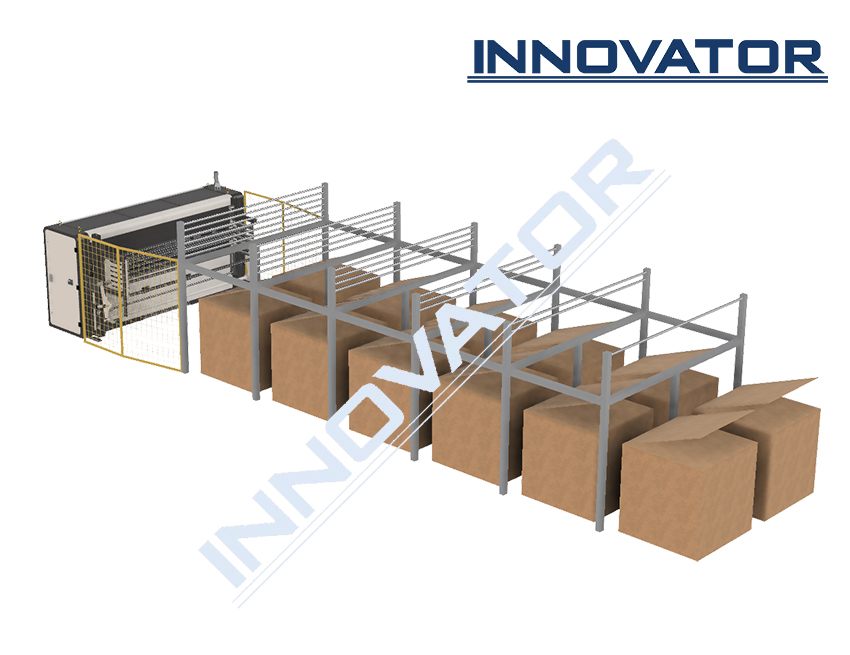

- automatic multi-fanfold feeding - three feeding trays (safety fence is included): Each feeding tray can have one fanfold, and can have up to 3 fanfolds in different sizes. (FitSize 2500)

.jpg)

- automatic multi-fanfold feeding - four feeding trays (safety fence is included): Each feeding tray can have one fanfold, and can have up to 4 fanfolds in different sizes. (FitSize 2500)

.jpg)

- automatic multi-fanfold feeding - five feeding trays (safety fence is included): Each feeding tray can have one fanfold, and can have up to 5 fanfolds in different sizes. (FitSize 2500)

.jpg)

- automatic multi-fanfold feeding - six feeding trays (safety fence is included): Each feeding tray can have one fanfold, and can have up to 6 fanfolds in different sizes. (FitSize 2500)

- automatic multi-fanfold side by side feeding - two feeding trays (safety fence is included): Each feeding tray can have two fanfolds in different sizes, and can have up to 4 fanfolds in different sizes. (FitSize 2500)

.jpg)

- automatic multi-fanfold side by side feeding - three feeding trays (safety fence is included): Each feeding tray can have two fanfolds in different sizes, and can have up to 6 fanfolds in different sizes. (FitSize 2500)

.jpg)

- automatic multi-fanfold side by side feeding - four feeding trays (safety fence is included): Each feeding tray can have two fanfolds in different sizes, and can have up to 8 fanfolds in different sizes. (FitSize 2500)

.jpg)

- automatic multi-fanfold side by side feeding - five feeding trays (safety fence is included): Each feeding tray can have two fanfolds in different sizes, and can have up to 10 fanfolds in different sizes. (FitSize 2500)

.jpg)

- automatic multi-fanfold side by side feeding - six feeding trays (safety fence is included): Each feeding tray can have two fanfolds in different sizes, and can have up to 12 fanfolds in different sizes. (FitSize 2500)

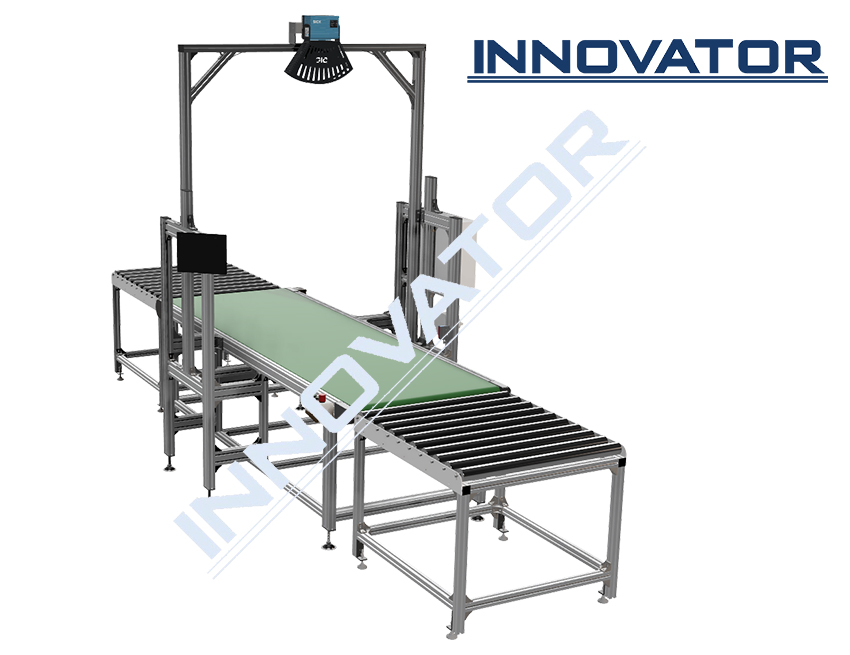

- 3D dimensioning system (measuring precision: 5 mm): It is connected to the FitSize box making machine. It is capable of measuring the product (cubic only) dimensions by the laser head that mounted over the conveying system, and transmit the data to the machine for the box production. * the min. product dimensions: 100 x 100 x 100 mm; the max. product dimensions: 1600 x 850 x 850 mm; the max. load: 120 kg

| Model | FitSize 2500 | FitSize 1600 |

|---|---|---|

| Cardboard Length | min. 400 mm | min. 400 mm |

| Cardboard Length (automatic sheets feeding) | 400 ~ 5000 mm | 400 ~ 5000 mm |

| Cardboard Width | 250 ~ 2500 mm | 250 ~ 1600 mm |

| Cardboard Thickness | 2 ~ 8 mm | 2 ~ 8 mm |

| Cardboard Basis Weight | outer liner ≥ 130 g/m2、fluting ≥ 100 g/m2 | outer liner ≥ 130 g/m2、fluting ≥ 100 g/m2 |

| Cardboard stacking height (automatic sheets feeding) | Up to 600 mm | Up to 200 mm |

| Cutting Tolerance | Longitudinal: Max. 0.2% Transversal: ± 2 mm |

Longitudinal: Max. 0.2% Transversal: ± 2 mm |

| Production Speed | 4 ~ 9 boxes/min. (depending on types and sizes) | 4 ~ 9 boxes/min. (depending on types and sizes) |

| Dimensions (L x W x H) | 1450 x 4450 x 1900 mm | 1450 x 3550 x 1900 mm |

| Electric Power | approx. 5 kw | approx. 5 kw |

| Net Weight | approx. 1900 kg | approx. 1450 kg |

| Color | RAL 8019 / RAL 9003 | RAL 8019 / RAL 9003 |

.jpg)

.jpg)