Box Making Machine (Fixtra)

Product Introduction

Thebox making machineis an automatic machine that combines slotting, die cutting, cutting and creasing in one. Just select a box type on the touch screen and a box with the fit size is then produced. It can reduce the manual adjusting and calculating error, and also the risk of getting injured. The switchover time between two orders needs only 5 seconds. Products can only be packaged with standard but bigger boxes BEFORE but they can be packaged with the fit-sized boxes with high efficiency for any kinds of industries NOW.

- GERMANY SICK sensor

- inconsistent creasing available

- JAPAN MITSUBISHI PLC control system

- independent slightly adjusting each size of L, B, H/li>

- standard equipped cardboard infeed stacking rack

- manual segment adjustment for infeed suction area

- Blades are made of special tool steel for extended life.

- continual infeed system to increase production speed

- machine voltage, size setting unit according to customer’s request

- The positioning time of the longitudinal units needs only 5 seconds.

- asymmetric slotting for special box type, such as 0200. 0209. 0212

- 15-inch HMI provides the user a clear operation interface and box details.

- Select a box type, enter the dimensions and a box with the fit size is then produced.

- auto adjustment of the front stopper height according to the cardboard thickness input

- The min. distance between longitudinal creasers / circular blades is 20 mm.

- Transverse unit can cut and crease, not limited by slotting knives length, for example, 0401 box type.

- 100,000 data which are frequently used can be archived in the system for improving the work efficiency.

- remote monitoring maintenance system for faster access from the manufacturer in case of machine breakdown.

- The interface will display the location of all the sensors on the machine. The user can know whether the sensors are activated by looking through the map.

- Equipped with Japan MITSUBISHI servo motor with high precision as standard. This contributes to the box making machine with great stability and accuracy of each mechanism to make fit-sized boxes.

- The HMI of the box making machine is already integrated with the industrial PC, the network connection can be done by using RJ45 cable or Wi-Fi. There is no requirement on an extra PC for the connection.

- Longitudinal circular blade can be interchanged with longitudinal creaser, it contributes to more box type (option).

- main working units

- - feeding unit

- motorized lower rubber roller

- servo-controlled speed

- creaser * 1

- circular blade * 1

- servo-controlled positioning

- circular blade with high-density teeth used for clean slitting edges

- creaser * 4

- circular blade of adjustable height * 4

- servo-controlled positioning

- circular blades with high-density teeth used for clean slitting edges

- die cutting – manual positioning: up to 4 sets (each 200 x 200 mm) – die molds to be made by customer

- die cutting – motorized positioning: up to 4 sets (each 200 x 200 mm) – die mold to be made by customer

- Extra longitudinal circular blade/creaser: 4 sets standard, optional up to 6 sets total

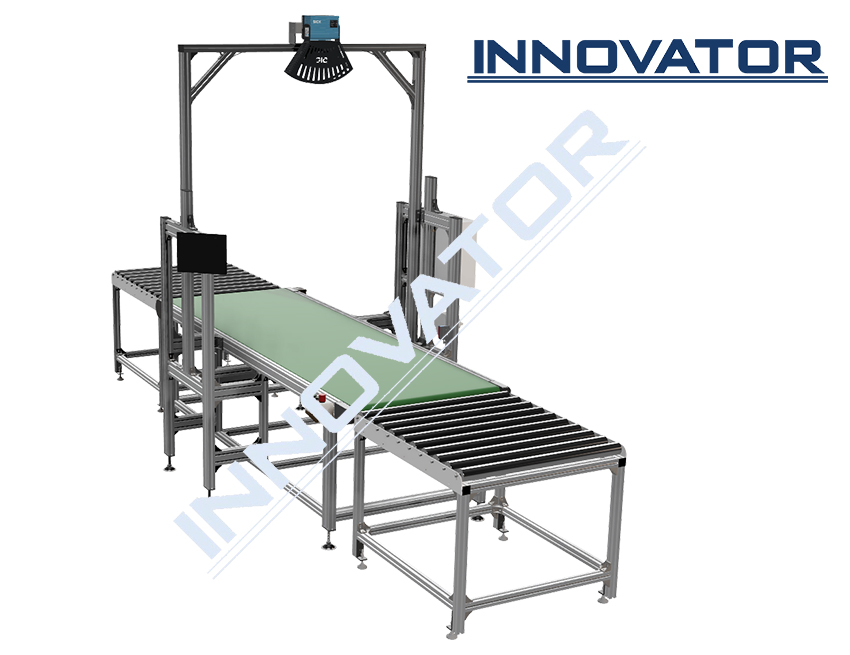

3-1. longitudinal circular blade: 6 ; longitudinal creaser: 43-2. longitudinal circular blade: 4 ; longitudinal creaser: 63-3. longitudinal circular blade: 6 ; longitudinal creaser: 6 - 3D dimensioning system (measuring precision: 5 mm): It is connected to the FitSize box making machine. It is capable of measuring the product (cubic only) dimensions by the laser head that mounted over the conveying system, and transmit the data to the machine for the box production.

Min. product dimensions: 100 x 100 x 100 mm Max. product dimensions: 1500 x 850 x 850 mm Max. loading: 120 kg Measurement tolerance: 5 mm Conveyor speed: 15 m/min. Electric power: 1 kw Dimensions (L x W x H): 4700 x 1800 x 2630 mm Net weight: approx. 230 kg

| Model: | Fixtra 2500 | Fixtra 1800 |

|---|---|---|

| Slotting knives length: | 500 mm | 350 mm |

| Slotting width: | 7 mm | 7 mm |

| Cardboard length: | min. 500 mm |

min. 500 mm |

| Cardboard width: |

200 ~ 2500 mm (depending on number of longitudinal units) |

200 ~ 1800 mm (depending on number of longitudinal units) |

| Cardboard thickness: | 2 ~ 8 mm | 2 ~ 8 mm |

| Cardboard basis weight: | outer liner ≥ 130 g/m2、fluting ≥ 100 g/m2、max. 240 g/m2 | outer liner ≥ 130 g/m2、fluting ≥ 100 g/m2、max. 240 g/m2 |

| Cardboard stacking height: | up to 320 mm | up to 320 mm |

| Box height of 0201: |

50 ~ 1600 mm with 500 mm slotting knives 50 ~ 1900 mm with 350 mm slotting knives |

50 ~ 900 mm with 500 mm slotting knives 50 ~ 1200 mm with 350 mm slotting knives |

|

Cutting tolerance: |

± 3 mm |

± 3 mm |

| Production speed: |

7 ~ 10 boxes/min. (depending on types and sizes) |

7 ~ 10 boxes/min. (depending on types and sizes) |

| Dimensions (L x W x H) : | 1650 × 3350 × 1600 mm |

1650 × 2650 × 1600 mm |

| Net weight: | approx. 3500 kg |

approx. 2800 kg |

| Electric power: | approx. 5 kW |

approx. 5 kW |

| Compressed air: |

6 bar |

6 bar |

| Color: |

RAL 8019 / RAL 9003 |

RAL 8019 / RAL 9003 |

.jpg)

.jpg)

.jpg)

.jpg)